IAC Program Overview

History of IACs

Industrial Assessment Centers, IACs, (formerly called the Energy Analysis and Diagnostic Center, EADC, program) were created by the Department of Commerce in 1976 in response to oil embargo and rising energy costs of the time. The program was specifically focused on helping small- and medium-sized manufacturing facilities cut back on unnecessary costs from inefficient energy use.

The IAC was moved to the U.S. Department of Energy (DOE) just after the DOE was formed in 1978. Shortly after, the scope of IAC assessments expanded to include evaluations of ineffective production procedures, excess waste production, and other production-related problems.

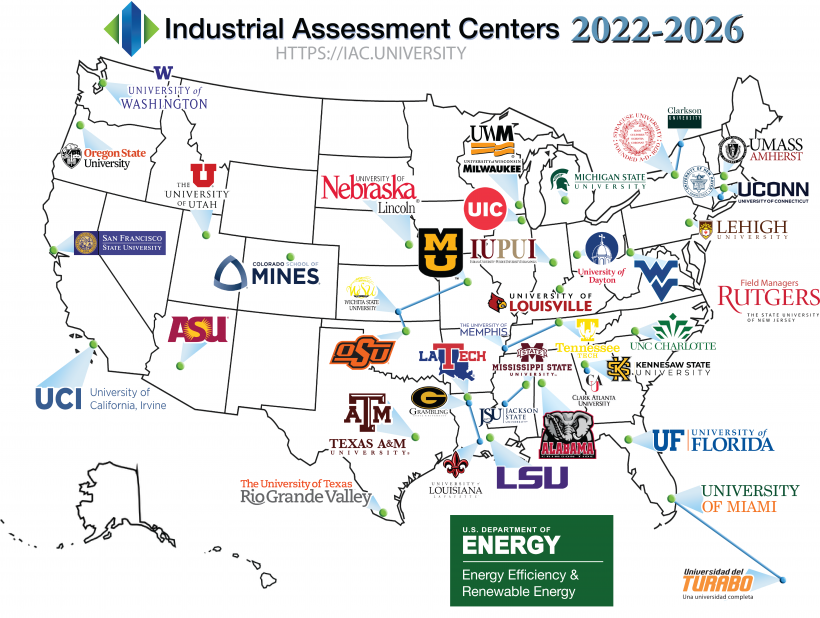

Currently, the IAC program is administered through the Advanced Manufacturing Office under the Office of Energy Efficiency and Renewable Energy of the DOE. There are currently 28 IACs that serve different regions of the United States:

Positive Impact of IACs

Assessments performed by IAC teams at other universities typically identify more than $130,000 in potential annual savings opportunities for every manufacturer assessed, nearly $50,000 of which is implemented during the first year following the assessment. Over 16,000 IAC assessments have been conducted.

In addition to money-saving benefits for the manufacturers that are assessed, the IAC program offers many other benefits. These include:

- Manufacturers can get impartial information to help make their facilities cleaner, greener, more productive, and more energy-efficient.

- There is no charge to the manufacturer for utilizing NIAC's services.

- University of Nebraska engineering students gain first-hand insights into the latest technologies in the field of energy consumption and energy efficiency.

- Students also receive hands-on training and gain skills in energy engineering.