Bioeconomy of Producing Specialty Chemicals in a Biorefinery

Chemical and Biomolecular EngineeringTeam Members

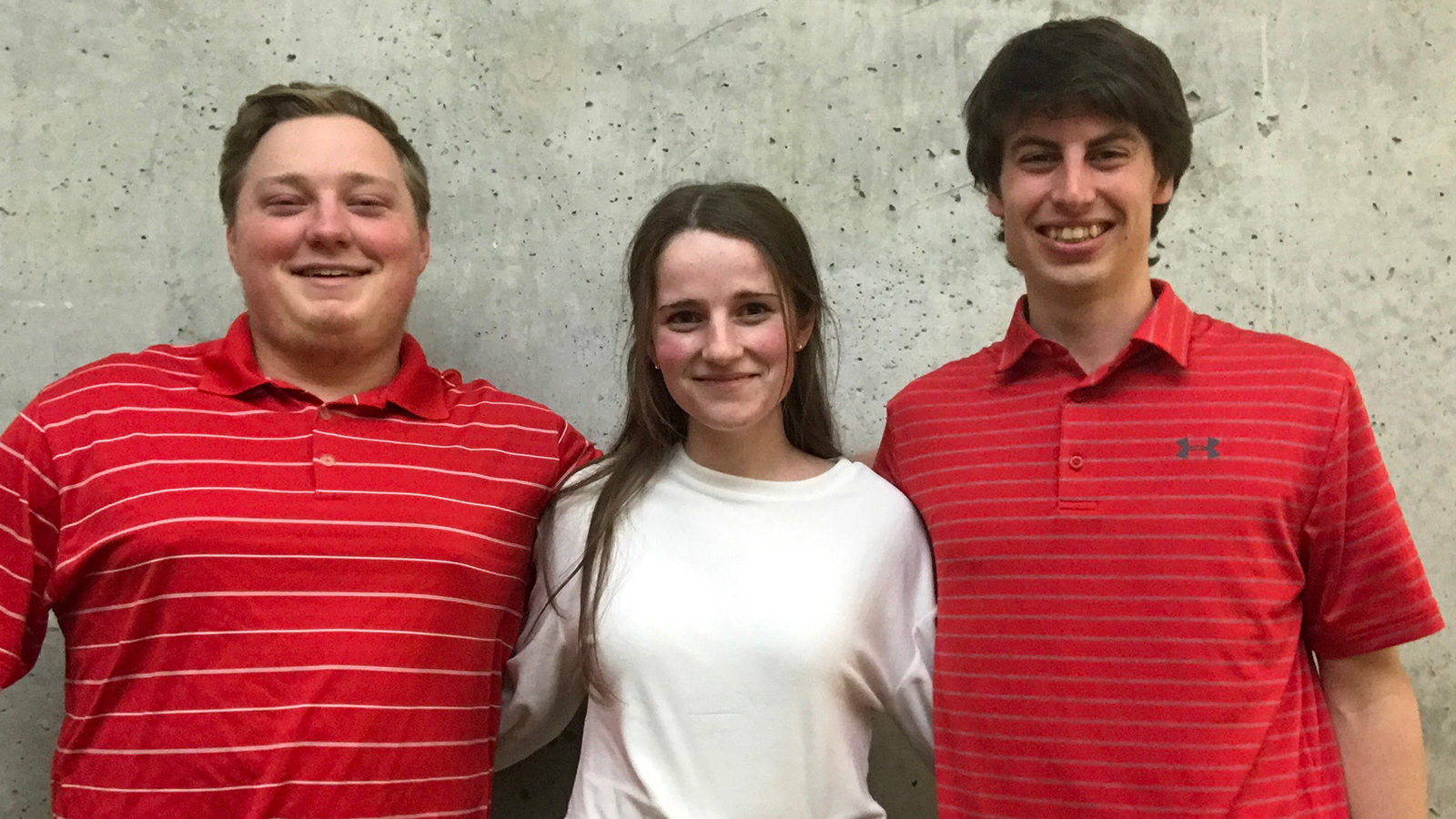

Adam Eddy, chemical engineeringEthan Glenn, chemical engineering

Ally Henry, chemical engineering

Faculty supervisor

Yasar DemirelThe chemical industry produces many important products; however, it is one of the biggest carbon producers and nonrenewable resource consumers. In this project, a team of chemical engineering students uses renewable feedstocks to produce multiple important chemicals that are used in industries ranging from bioplastics to pharmaceuticals. This is accomplished by utilizing microorganisms to ferment corn stovers and other low-quality feedstocks that don’t take away from humanity’s food security. This shows that the concept of a bioeconomy and biorefinery is possible in the near future.

Adam Eddy discussed the team’s project and the senior design capstone process:

Q: How did this team come to be working on this project? Were you assigned by a faculty advisor or did you have to come up with the idea?

Eddy: Our team was provided a list of possible projects in the fall of 2021. As young engineers, we have learned a lot about sustainable and green engineering and, thus, wanted to choose a project that focused on new processes that focused on sustainability. We also learned about the concept of a biorefinery and bioeconomy from our advisor, Dr. Demirel.Q: Describe the work experiences that took you from the beginning (your first moments as a team) to where the project is now.

Eddy: We began our project by doing a literature survey into our process. We did lots of research into pretreatment of lignocellulose feedstocks, different types of microorganisms to ferment the treated feedstock into succinic acid, different catalysts to transform our succinic acid into our desired product of 1,4-butanediol, and various separation processes to separate our main product from our byproduct of gamma-butyrolactone and waste streams.Then, we combined all these pieces into our current process and determined our inputs, outputs, and utilities used by making a block flow diagram. Next, we sized and input all the equipment into a computer aided design software called Aspen Plus to simulate the process. Once we got the simulation to smoothly run and converge all mass and energy balances, we began sensitivity analyses to determine what steps of the process we needed to optimize.

After optimizing all reactions, separation steps, and other aspects of the simulation, we performed safety, economic, and sustainability analyses to determine that our process was feasible.

Q: How will your design have an impact on people or the world?

Eddy: Our project utilizes the idea of a bioeconomy. We use renewable feedstocks that close the bioeconomy loop so that humanity as a whole can be more sustainable. We also focus on the use of lignocellulose feedstocks, which do not take away from humanity’s food supply. Our project shows that the concept of biorefineries can be economically and sustainably feasible.The petrochemical industry made a massive contribution to the modern world by refining multiple products from a single feedstock of oil. Our project aims to make a similar impact by refining multiple products from a single renewable feedstock. Furthermore, our process is based on the use of corn stovers, which are usually a waste product left over in corn fields. We could give farmers one more product to sell to increase their bottom line.