Heat removal is a major limiting factor in modern devices including computer electronics, generators, electric vehicles, and nuclear power cooling. A common method for enhancing heat removal is to use boiling. By modifying the surface, boiling heat transfer efficiency can be increased along with increasing the safety margins for operation. One surface modification technique is femtosecond laser surface processing (FLSP), a technique that the University of Nebraska-Lincoln is a world leader in. This technique uses an ultrafast-short pulse laser to create micro and nanoscale surface structures, a surface functionalization that enhances two-phase heat transfer.

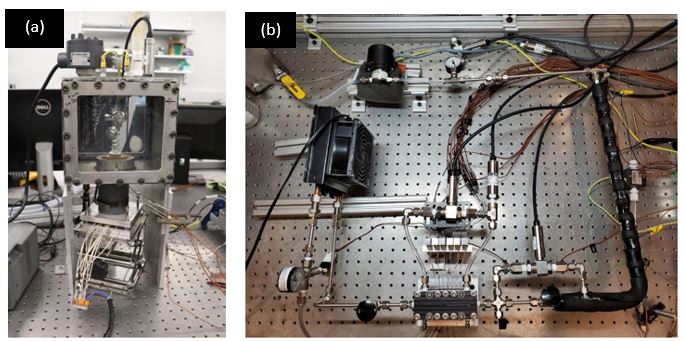

The Multiscale Heat Transfer Lab (MHTL) uses these functionalized surfaces in two experimental configurations: pool boiling and flow boiling. For pool boiling, the surface is heated in a stagnant chamber of water. In flow boiling, water is pumped through a channel of FLSP surfaces. In each of these configurations, the heat dissipated into the liquid is measured as a function of the temperature of the functionalized surface.

(a) Pool boiling setup, and (b) flow boiling setup.

Surface functionalization aims to reduce the surface temperature for a given rate of heat dissipated. This surface temperature reduction extends a device's lifetime by reducing thermal wear and increases the maximum amount of heat a surface can safely dissipate before failing. Using FLSP-modified aluminum surfaces, the heat transfer coefficient was recently enhanced by 680%. Additionally, two unique phenomena known as boiling inversion and hysteresis occur regularly when boiling with FLSP surfaces. During boiling inversion, the surface temperature reaches a maximum and decreases with a further increase in the heat flux. This leads to even further enhancements in energy transport efficiency. This phenomenon has been shown to occur in both pool and flow boiling configurations that use FLSP surfaces. Hysteresis has also been studied in pool boiling research; reducing the heat flux from levels close to the critical heat flux (the highest heat flux before failure), a different path is followed as a function of the surface temperature than the path followed when the heat flux is increased.