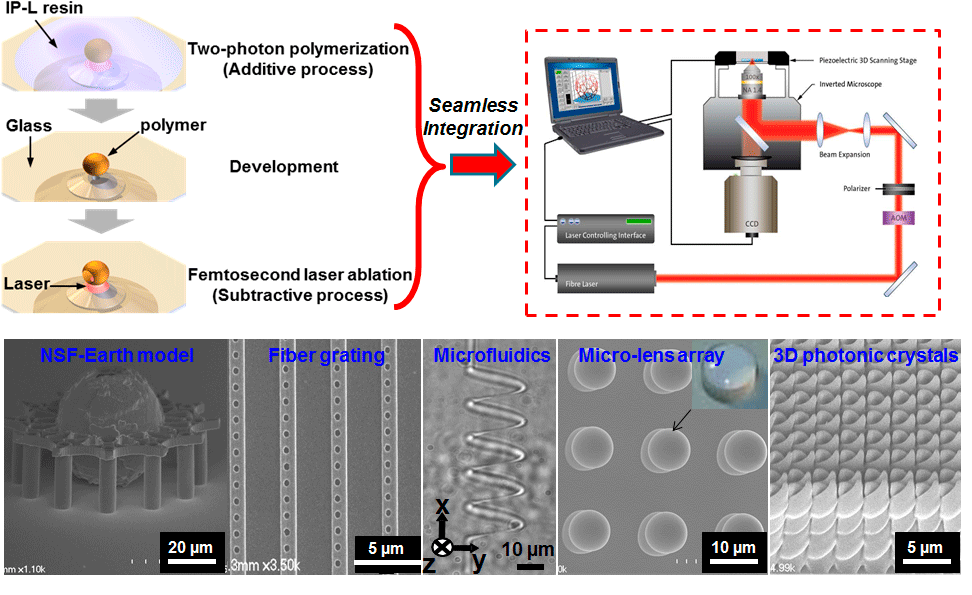

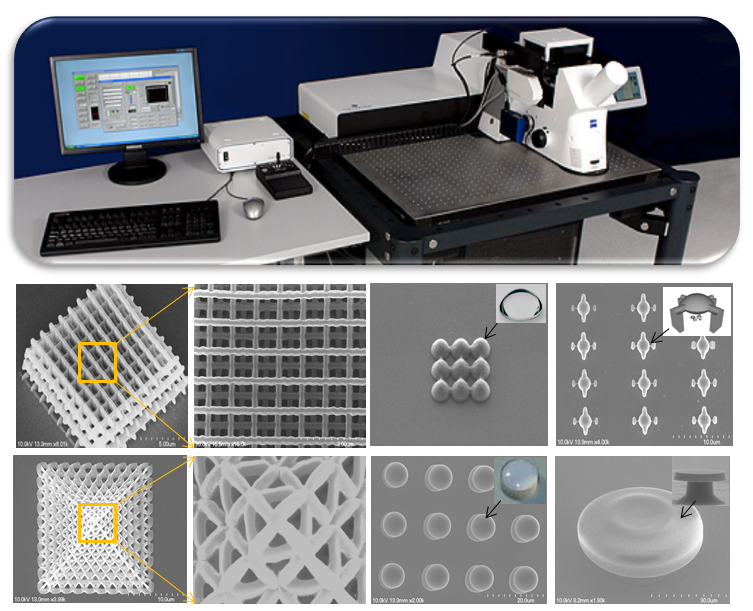

3D micro/nanofabrication via laser direct writing

This research area is to develop a single-step laser direct writing technique to achieve designable, high-efficient 3D micro/nanofabrication. The new technique will combine the additive two-photon polymerization (TPP) and the subtractive multi-photon ablation (MPA) into a single-step fabrication process to achieve the comprehensive 3D micro/nanofabrication. The success of this project will enable the fabrication of arbitrary complex 3D micro/nanostructures which are promising for a wide range of applications such as integrated optics, micro-fluidics, and microelectromechanical systems.

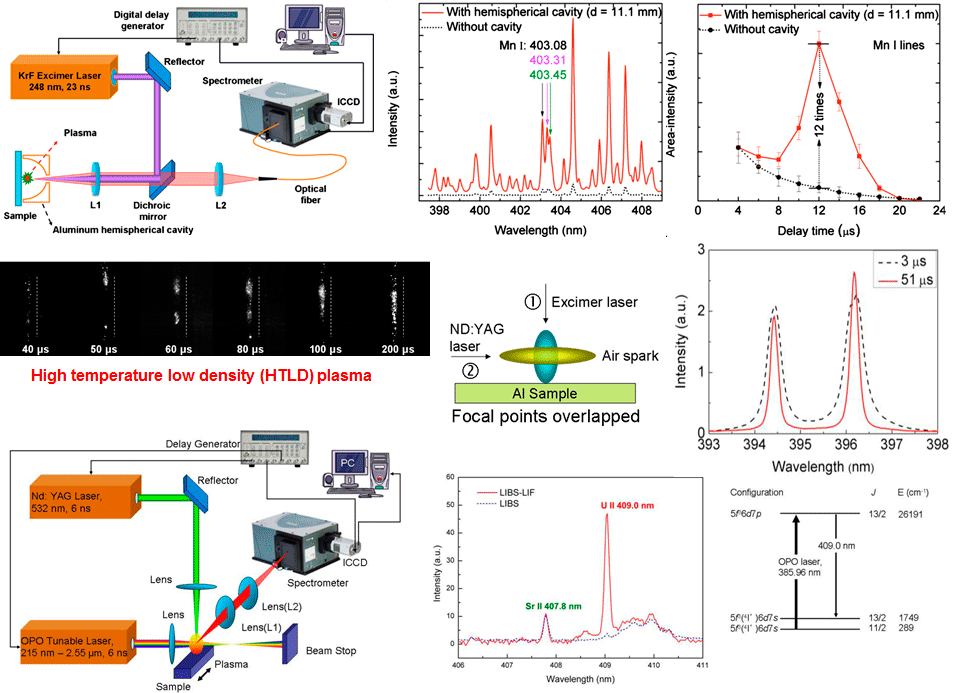

Analyses of trace materials

The goal is to improve sensitivity and accuracy in analysis of trace contaminants/impurities in solid samples using laser-induced breakdown spectroscopy (LIBS) through spatial confinement of plasmas. In addition, laser-induced fluorescence will be combined to achieve a detection limit to 1 ppm. Another related research topic is Laser Assisted Mass Spectroscopy (LA-MS) in the domain of isotope detection and nondestructive analysis.

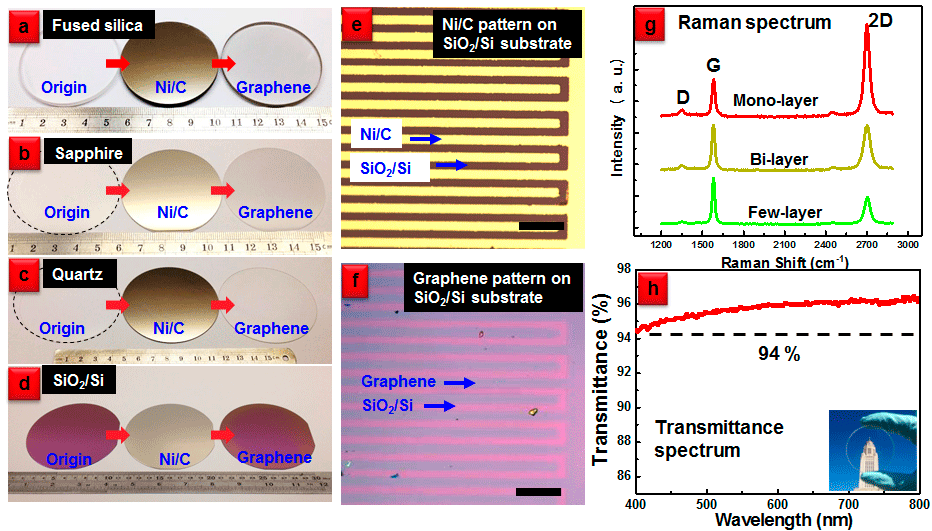

Direct growth of graphene on dielectric surfaces via RTP

This research area is to develop a scalable, cost-effective and transfer-free process for high-quality, wafer-scale graphene production on various dielectric surfaces. A novel synthesis method of solid-state transformation via rapid thermal annealing technique will be developed and studied, in which the growth mechanism and controllable graphene growth will be systematically investigated. The success of this research will provide a unique solution to the existing challenges in the current graphene production and promote the graphene-based industrial application.

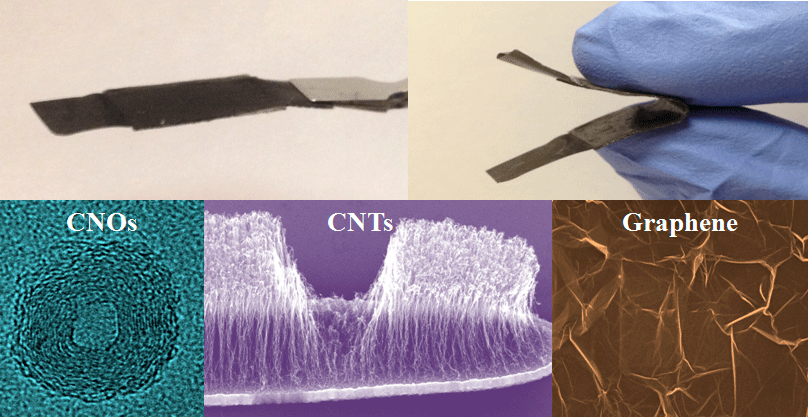

Energy Storage Devices (Supercapacitors, Batteries, ...)

Supercapacitors, which store energy through the electric double layer formed on the electrodes, fill the gaps between conventional capacitors and batteries in terms of energy and power densities. In our group, the research on supercapacitors mainly focused on:

- Improvement of the energy density of supercapacitors

- Development of flexible solid-state supercapacitors for the applications in portable electronics

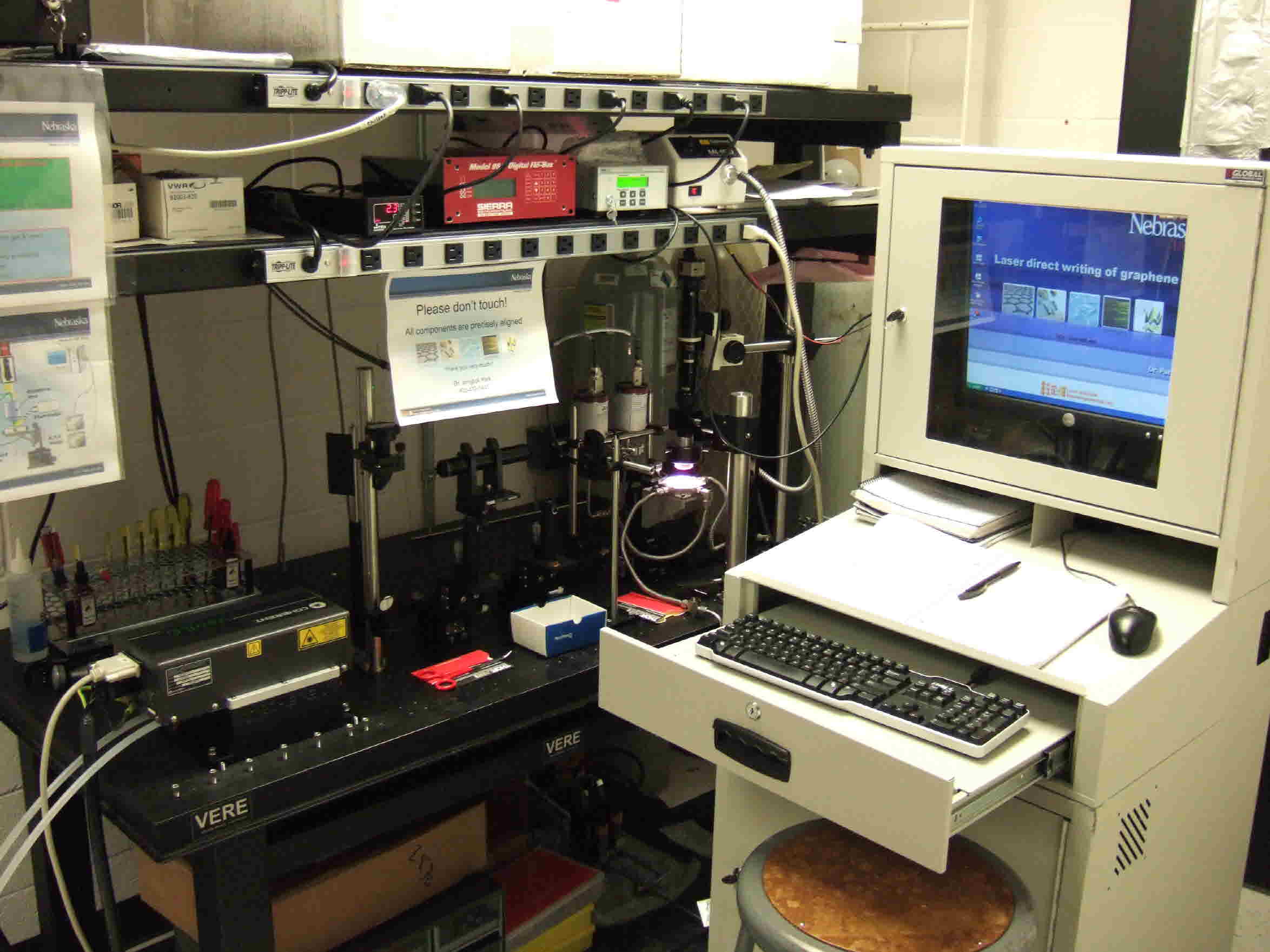

Laser direct writing of graphene patterns

Graphene will be a key material in emerging technologies due to the ease of manipulation and their unique properties. Up to now, chemical vapor deposition (CVD) is the most promising method due to the benefits of large-scale production of graphene and patterning process for various applications. However a multi-step process with long processes time has to be improved for process innovations. Thus, the overarching goal of this project is to develop an innovative technology of ultra-fast single-step growth for high quality graphene patterns for various applications.

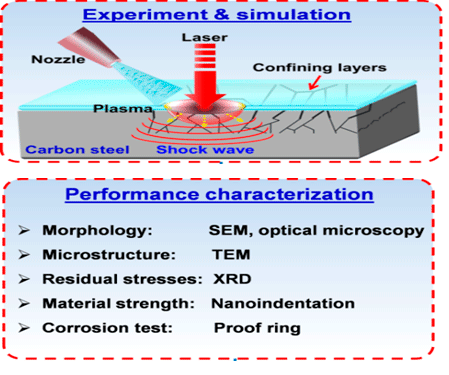

Microstructure and corrosion resistance improvement of alloys by Laser shock peening

This research area aims to improve corrosion resistance of alloys like Al alloy and low carbon steel using laser induced shock wave with ultrahigh pressure, which causes deep compressive residual stress and microstructure refinement on alloy surface due to high strain rate phenomena. Nano-indentation, X-ray diffraction, metallographic microscope, SEM, and TEM are combined for characterization and analysis. The success of this project will enable the preventing or restoring of stress corrosion cracking in pipeline steel and the operation, maintenance, and support costs reducing associated with the pitting, cracking, and sensitization of 5000 series Al alloy.

Multi-energy material synthesis

This research area is to develop a new multi-laser-beam and low-temperature approach to synthesizing electronic materials on various substrates with optimized efficiency, improved quality, and minimum thermal stress. This synthesizing technique will be customized to specific film/substrate systems through designed reaction paths involving excitation of the precursor molecules, photodissociation and ionization of excited precursor molecules, and controlled plasma cooling and film formation.

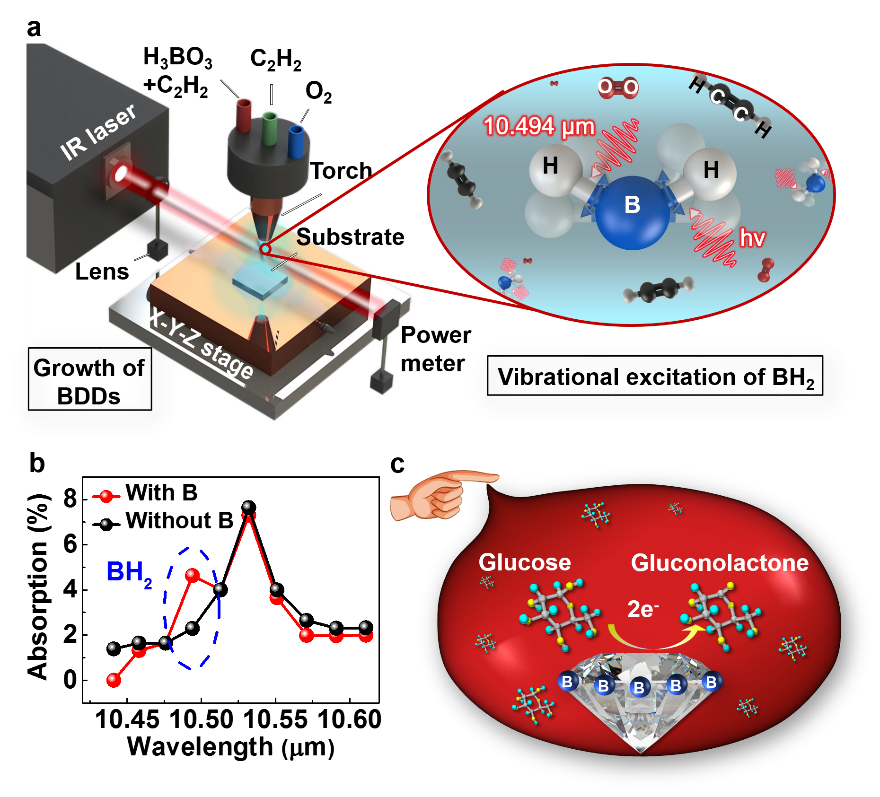

Multi-energy processing in fast fabrication of large-area, high-crystalline boron-doped diamond (BDD) electrodes for wastewater treatment

High-quality crystals, such as diamonds, suffer from lattice degradation with the impurity doping, severely limiting the scientific functionalities and applications of the crystals. The In-situ B doping during chemical vapor deposition (CVD) induces a large variation of gas chemistry and makes diamond losing phase stability, leading to severe crystallinity degradation. Lasers provide a unique means of controlling chemical reactions by directionally coupling energy into specific transitions of selected reactant molecules, which allows for distinguishing the effects of different reacting channels on doping and crystallization. In this work, we explore the possibility to utilize a multi-energy processing route to maintain lattice integrity during the growth of crystals with impurity doping. The research is implemented through the case of stabilizing diamond crystallization during boron (B) doping process for fabrication of large-area, high-crystalline B-doped diamond (BDD) electrodes to be used towards water purification and electrochemical sensing.

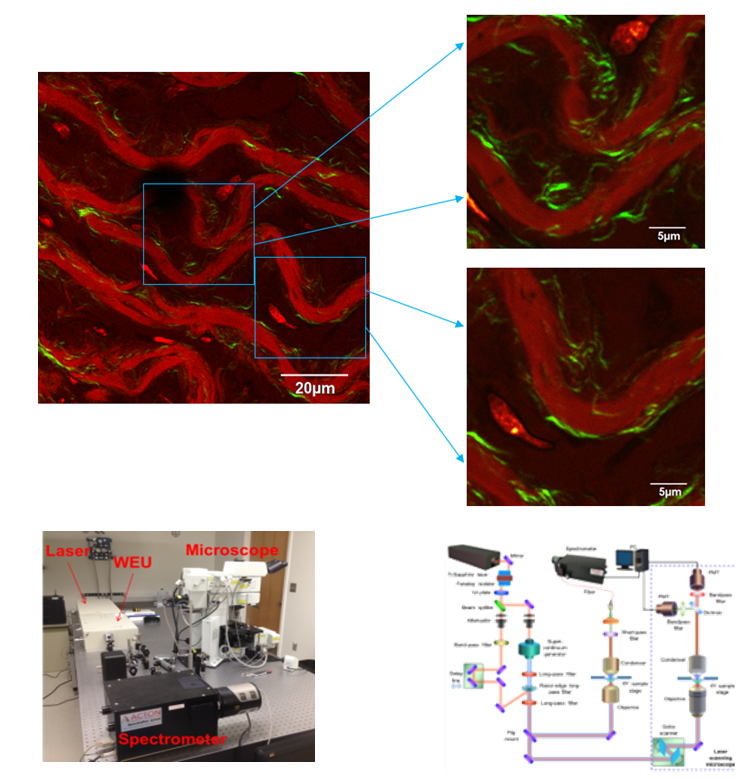

Multifunctional CARS (Coherent Anti-Stokes Raman Spectroscopy) Imaging

CARS microscopy has been used to visualize living cells with contrast of different vibrational modes, including the phosphate stretch vibration (DNA), amide I vibration (protein), OH stretching vibration (water), and the CH group of stretching vibrations (lipids). Due to its nonlinear optical effect, CARS is much more efficient than spontaneous Raman spectroscopy, enabling faster, more sensitive analyses with less photo exposure. Moreover, CARS circumvents the need for extrinsic labels, allowing observation of dynamic, phenomena for which tags are not available. Further work will be focused on measurement of different samples, imaging multimodality and CARS spectroscopy development, spatial resolution improvement for measurement of nanomaterial.

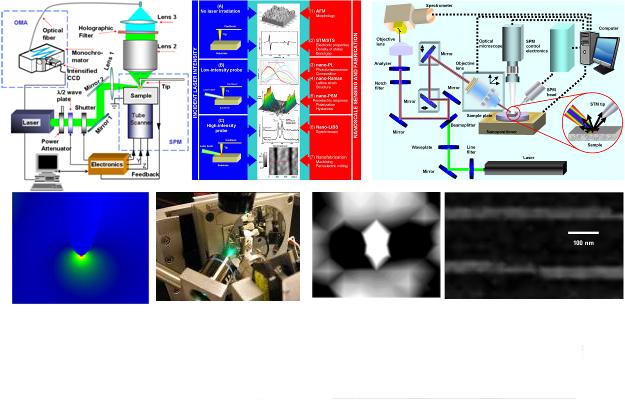

Nanoscale processing and characterization using laser-assisted scanning probe microscope

This research area is to develop a new multi-laser-beam and low-temperature approach to synthesizing electronic materials on various substrates with optimized efficiency, improved quality, and minimum thermal stress. This synthesizing technique will be customized to specific film/substrate systems through designed reaction paths involving excitation of the precursor molecules, photodissociation and ionization of excited precursor molecules, and controlled plasma cooling and film formation.

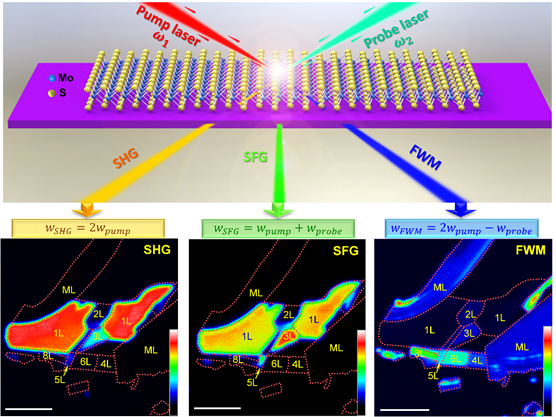

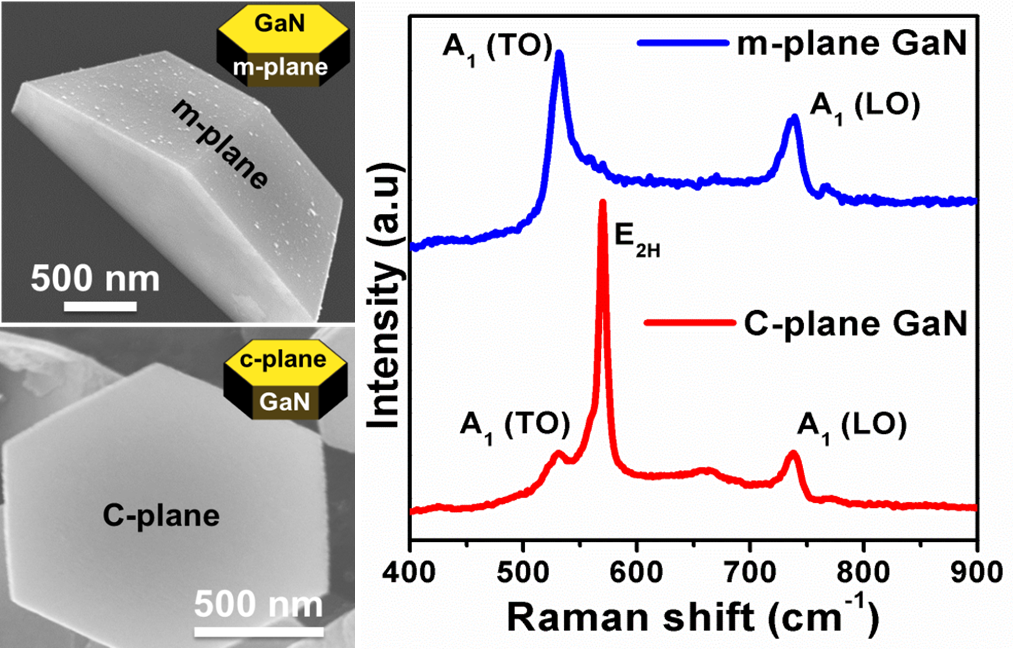

Nonlinear Optics on 2D Layered Structures

Van der Walls layered structures, primarily graphene and beyond-graphene 2D crystals, such as transitional metal dichalcogenides (TMDs) and black phosphorus, have recently attracted immense interest due to their unique physical properties and potential application in electronics, optoelectronics, and energy harvesting. Recently, nonlinear optical responses (or ultrafast electronic and structural responses) in 2D layered structures have gained great interest. Our goal is to control preparation of various kinds of high-quality 2D layered structures and develop multimodal nonlinear optical imaging methods to characterize their critical properties, including crystal orientation, chemical dynamics, and ultrafast dynamics. This method has the advantages of versatility, high fidelity, easy operation, and fast imaging, paving the way for comprehensive characterization of van der Waals layered structures for fundamental research and practical applications.

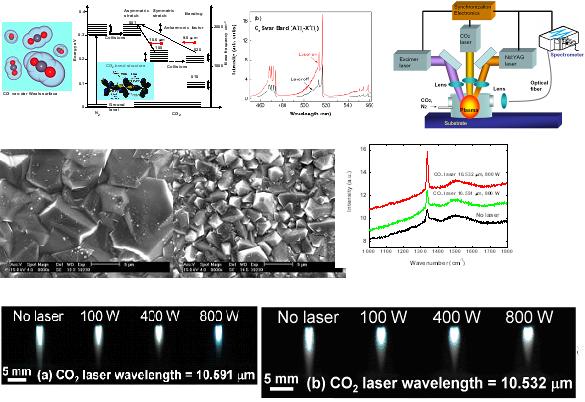

Rapid growth of GaN epitaxial layers at low temperatures using laser-assisted MOVPE

The goal is to synthesize highly crystalline GaN epitaxial layers at low temperatures using laser-assisted metal organic vapor phase epitaxy (L-MOVPE). In this approach, the ammonia (NH3) molecules will be dissociated by resonantly exciting one of its vibrational modes using a wavelength-tunable CO2 laser. The resonant excitation will break the bonding of the NH3 molecules at reduced temperature compared to the conventional methods. The low temperature growth will minimize the thermally induced defects of GaN epitaxial layer. This method can be extended for the growth of III-nitrides and other nitride-based materials.

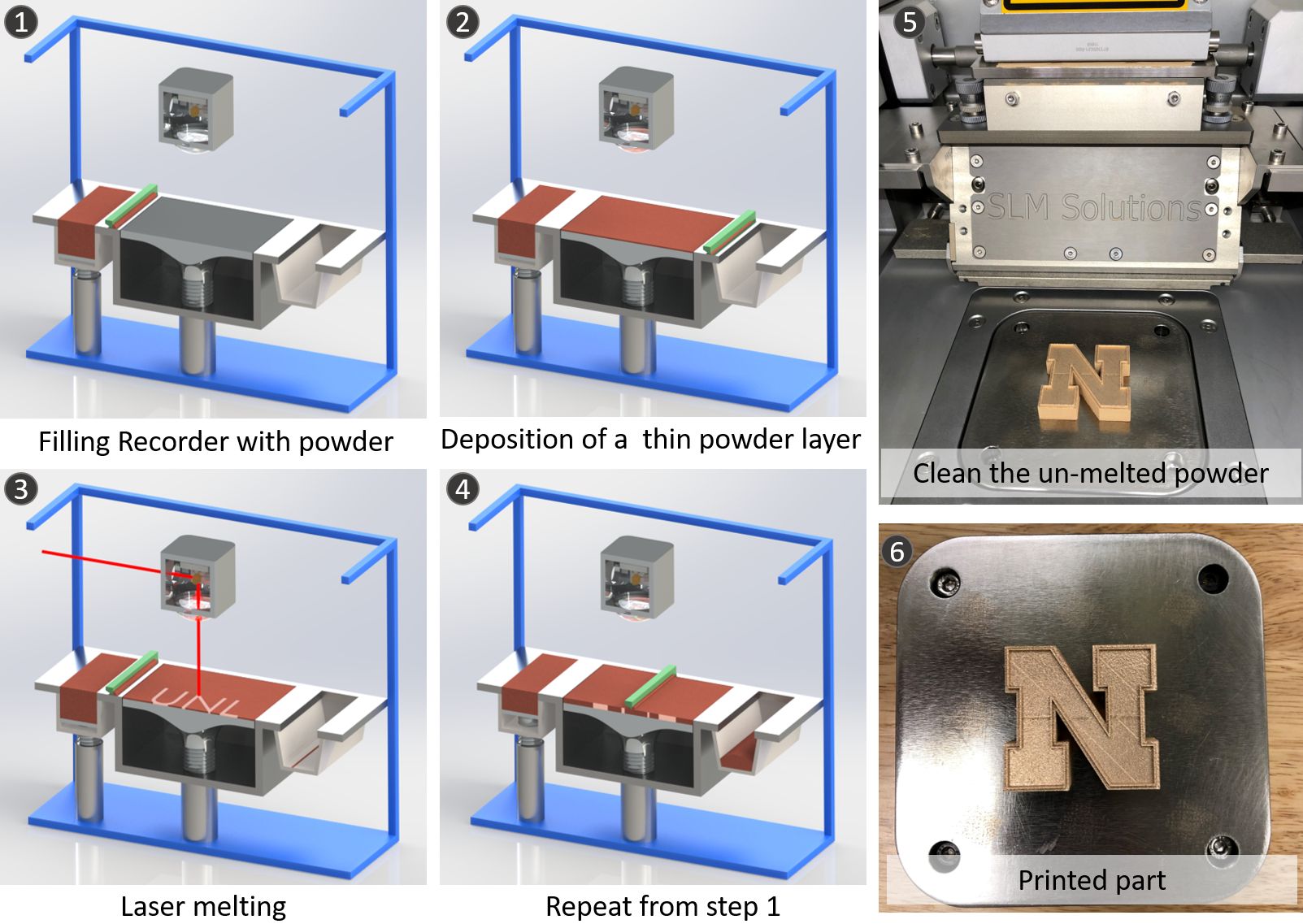

Selective Laser Melting (SLM) Machining

Selective Laser melting (SLM) is an additive manufacturing (AM) process in which a laser is used as the heat source. The part is printed layer by layers permitting to manufacture complex shape and architecture which can not be achieve by conventional methods. The 3D printer is equipped with a high power fiber laser (400W) allowing to print high melting point materials such as metals, ceramics or even composite materials. Our research focuses on the development of printing parameters for materials which are not available yet for AM and to correlate the printing parameters to the part’s physical properties.

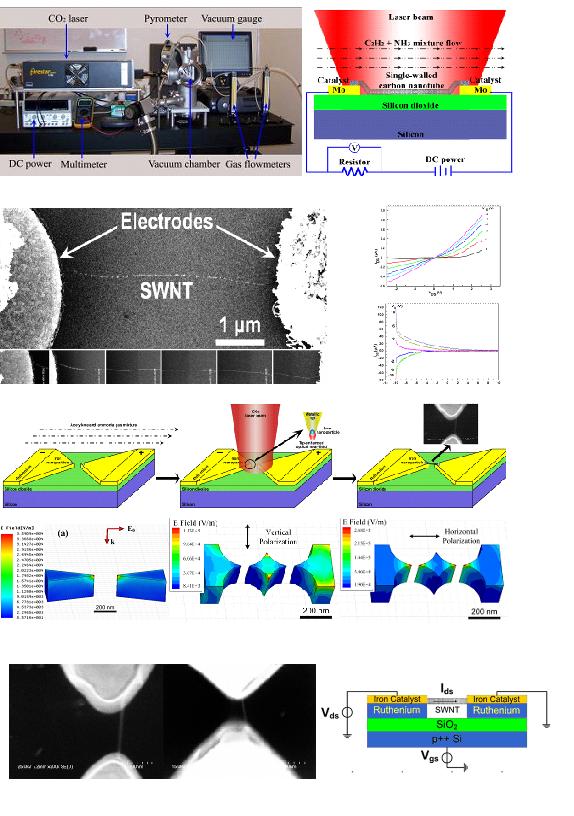

Self-aligned growth of carbon nanotubes (CNTs) for nanoelectronic device fabrication

Carbon nanotubes (CNTs) are critical building blocks for various electronic and photonic devices because of their unique electrical, optical, and mechanical properties. Infrared sensors, gas sensors, memories, solar cells are being developed using CNTs. We are developing technologies for viable and cost-effective mass production of CNT-based electronics, including the development of a new laser-based process to achieve self-aligned growth of nanotubes to connect conductive electrodes at low substrate temperatures to form electronic devices.

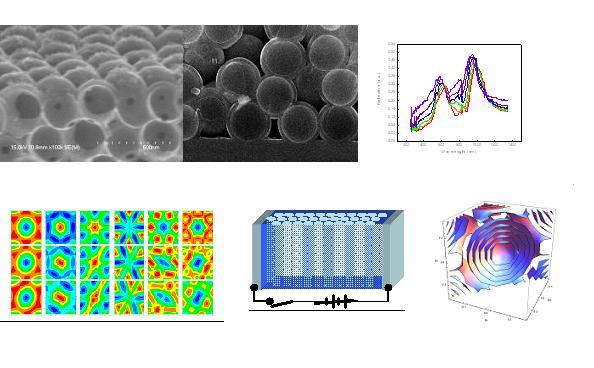

Tunable photonic bandgap crystals

This research addresses the fundamental science and practical engineering approaches for design, fabrication, and characterization of electrically-tunable 3-D photonic bandgap (PBG) crystals with integrated functionalities of positive refraction, negative refraction, and total reflection.

Two-photon polymerization

The goal of this project is to fabricate arbitrary 2D and 3D micro structures with a sub-100-nm resolution based on two photon polymerization in UV-curable photoresists. TPP can be simply realized using a tightly focused femtosecond (fs) laser beam to draw 2D and 3D nanostructures inside a photosensitive polymer. The direct laser writing technology opens up a multitude of applications, such as photonics, microfluidics, micro mechanical microstructures, and optics.