For the past 50 years, manufacturers have considered carbon fiber a dream material: Though individual fibers are thinner than a strand of human hair, they can be twisted together and fused with a matrix material to form a lightweight composite that is stronger than steel, twice as stiff and a good conductor of heat. And, unlike metals, the material doesn’t crack over time. It’s been used in a wide range of applications, including air and spacecraft, cars, buildings, medical devices and sports equipment.

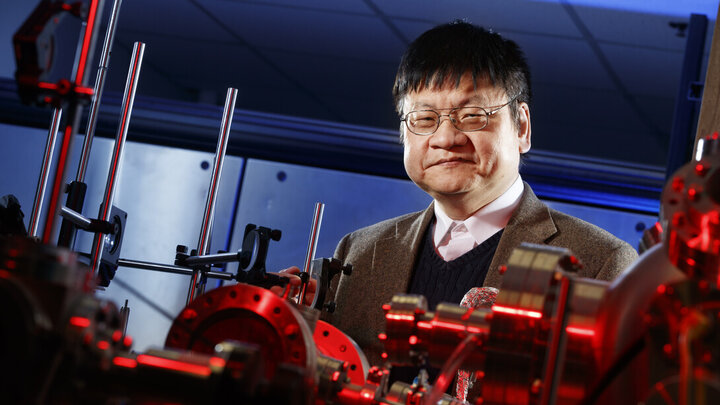

But carbon fiber has a major drawback, said Husker engineer Yongfeng Lu, an expert in carbon materials. Under extreme temperatures — encountered routinely in the aerospace industry, for example — carbon fiber oxidizes, meaning it reacts with oxygen in the air and burns, just as wood does when combined with enough heat and oxygen. Oxidation quickly diminishes the dream-like qualities of carbon fiber, particularly its strength.