Calendar Icon

Nov 08, 2021

Person Bust Icon

By Karl Vogel

![]() RSS

Submit a Story

RSS

Submit a Story

RELATED LINKS

Manufacturing of rubber has typically produced items with limited functionality in terms of its electrical and thermal properties.

To increase ways that rubber can be used, rigid fillers – such as carbon black or copper– are often included that increase their electrical and thermal properties, however these rigid fillers can detrimentally change the mechanical properties by making the material stiffer and more brittle.

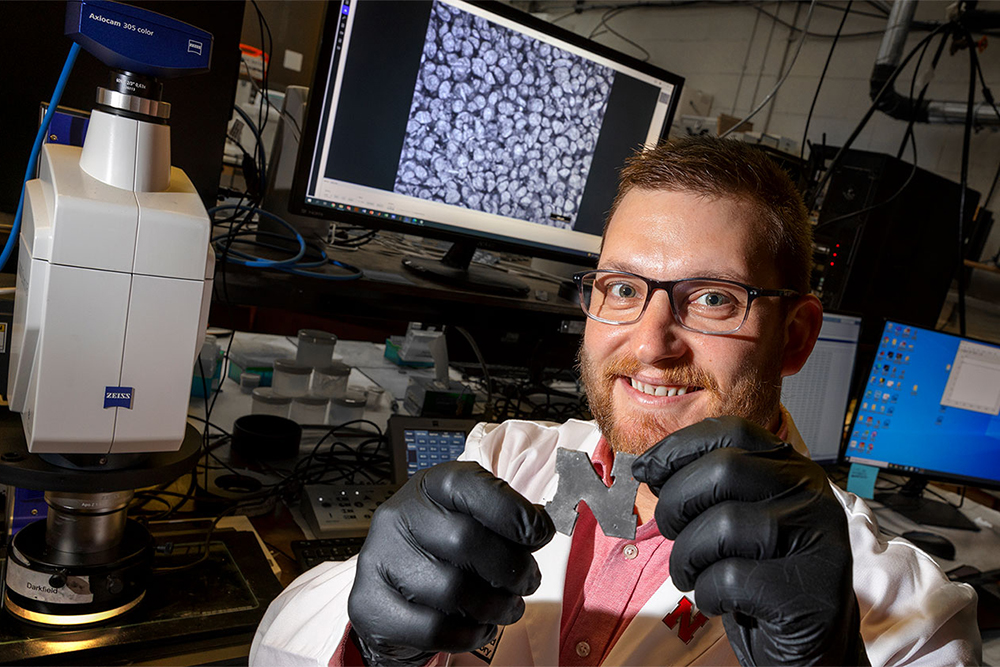

Through a three-year, $354,293 grant from the National Science Foundation, Nebraska engineer Eric Markvicka and Virginia Tech's Michael Bartlett are creating new ways to manufacture rubber composites by changing the shape of liquid phase fillers – such as room temperature liquid metals – to better control the printed materials electrical, thermal and mechanical properties. Aaron Haake, a senior mechanical engineering major, has been leading the work from Markvicka's group in Nebraska.

"Rubber composites with liquid metal fillers offer new opportunities to conduct electricity and/or transport heat in wearable electronic devices, inflatable structures or soft robotics, which require materials that are soft, highly elastic and mechanically compatible with the human body or host structure," said Markvicka, assistant professor of mechanical and materials engineering.

Current manufacturing processes, especially 3D printing, call for materials with fillers – or inclusions – that are typically rigid and are in shapes that cannot be altered. These filled rubbers are printed in a liquid state that can be cured into a rubber composite of complex geometry.

By using materials with liquid phase fillers, such as liquid metal, manufacturers can change the shapes of the fillers during manufacturing and, thus, change the properties of the product. Elongating the droplets in a certain direction or multiple directions, Markvicka said, allows manufacturers to "tune" the rubber to be softer, more stretchable and a better conductor of electricity and/or heat, while creating a more versatile, durable product.

"Using an open-source 3D printer with extrusion-based print head, we can program the liquid inclusion microstructures within these materials in ways that are currently not possible with existing methods," Markvicka said. "These materials are initially electrically insulating, which is important in coatings that require electrical insulation to prevent electronics from short-circuiting."

While the current plan is to use these manufacturing processes on rubber-based products, the approaches could apply to other extrusion processes that rely on the pressure driven flow of emulsions, such as 3D printing of food products.

"We aim to study how the properties of the liquid silicone rubber, liquid phase fillers and printing conditions influence the programming of liquid inclusion microstructure during 3D printing," Markvicka said. "The manufacturing approach will offer new strategies for processing emulsions and the ability to create novel materials with unique combinations of thermal, electrical and mechanical functionalities."

Submit a Story