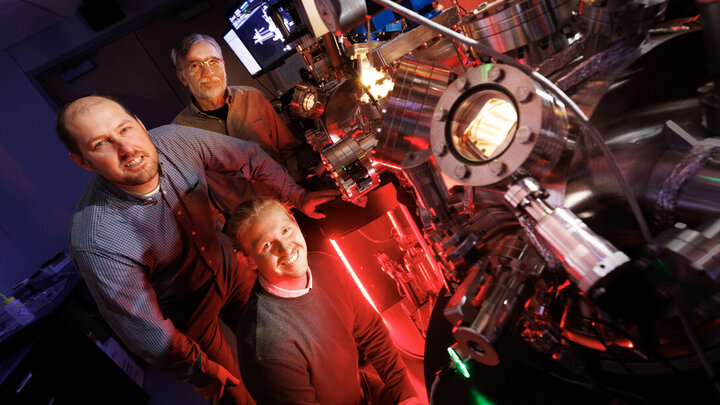

The College of Engineering's Center for Electro-Optics and Functionalized Surfaces is now home to a first-of-its-kind laser in the United States to be used for a specialized method of surface modification.

This approach — called femtosecond laser surface processing — beams an ultrafast laser at a metal material, changing its micro- and nanoscale features and its chemistry. These changes confer properties conducive to a wide range of applications in space, defense, medicine and beyond.

Because it offers advantages over traditional surface modification methods, FLSP is considered a manufacturing method of the future and is an area in which Husker researchers have led the way for more than a decade. The new laser, purchased with funding from the Defense University Research Instrumentation Program, comes at a pivotal time in the field.

Though researchers have been functionalizing surfaces with lasers for about two decades, the complex methods and available technology allowed production of only tiny samples. Now, the university will be able to produce larger quantities of raw materials with tailored surface properties.

"The new laser will be able to functionalize about 50 times faster than we can right now," said George Gogos, center co-director and Wilmer J. and Sally L. Hergenrader Professor of Mechanical and Materials Engineering. "There are members of the space and defense industries that are aware we have this laser, and there's an interest for additional work, funding and collaborations because of this scalability."