Calendar Icon

May 08, 2020

Person Bust Icon

By J.S. Engebretson

![]() RSS

Submit a Story

RSS

Submit a Story

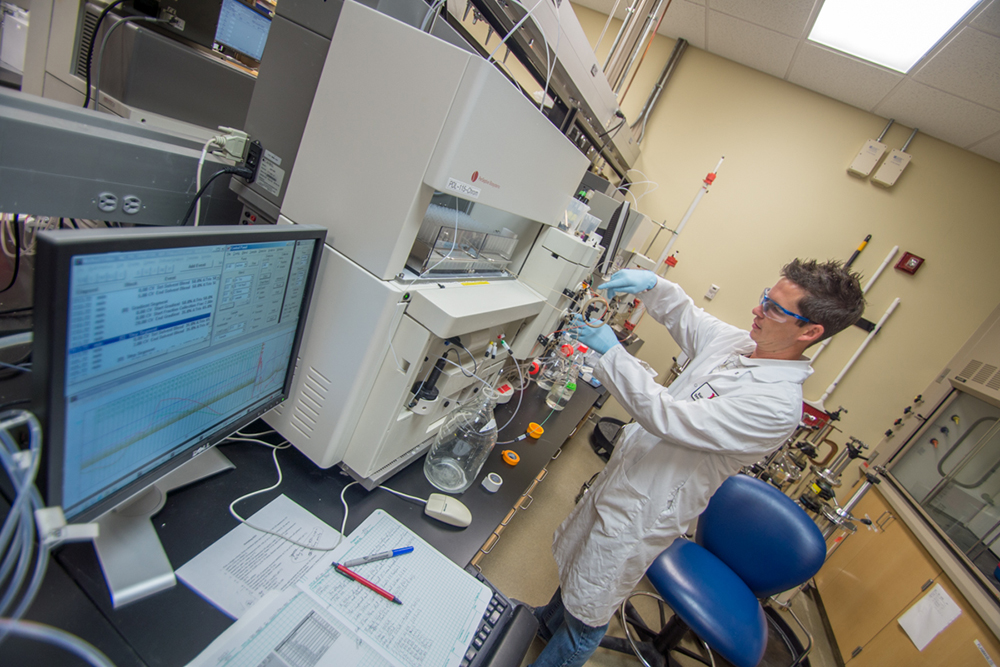

The development of a recombinant protein for use as a treatment to provide compassionate care for coronavirus patients is underway at the Biological Process Development Facility (BPDF) in the College of Engineering at the University of Nebraska-Lincoln.

The BPDF is working with a preclinical drug discovery company using its proprietary genetic technology platform to produce a recombinant protein as a biotherapeutic for COVID-19 patients who may have few options left for treatment. According to Dennis Hensen, project manager, clinical trials for this treatment are being fast-tracked for a possible July start.

The facility, located in Othmer Hall on UNL’s City Campus, specializes in process development and GMP (Good Manufacturing Practices) production of recombinant peptides and proteins that are suitable for non-clinical and clinical studies. The BPDF develops compliant manufacturing processes and test methods used in the production of drugs and other biologics, and produces bulk drug substance under GMP suitable for non-clinical and clinical trials. The BPDF also produces bulk intermediates for further processing, and industrial enzymes for GMP manufacturing.

“The protein we’re producing will be used to provide a treatment option for people with advanced cases to hopefully prevent the need or reduce the time on a ventilator,” said Scott Johnson, production manager. He noted that this treatment is not a vaccine but rather a biotherapeutic.

BPDF researchers were already conducting development work with this protein when the company determined that their protein could have a potential use as a response to the effects of the coronavirus, Hensen said. While this is being manufactured on a small scale for now, they are ramping up to produce more volume for testing.

Johnson said that approximately 20 scientists and technical professionals, including some students, are currently working on this project. Due to the complexity of their work and strict guidelines for producing GMP materials, the BPDF already has extensive cleaning and safety protocols in place, but will introduce further safety measures for employees during the COVID-19 response, he said.

According to Cory Smathers, business operations manager, the BPDF has other COVID-19-related projects in early development stages – one involves creating a working group with a large biopharmaceutical company and several universities for development of a potential vaccine for the coronavirus; a second would produce components to support diagnostic kits.

Submit a Story