Agricultural Engineering

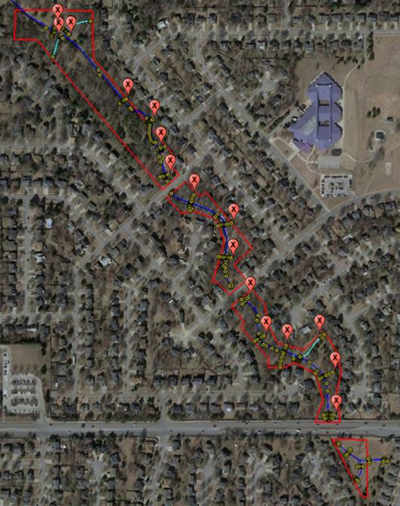

Cripple Creek Streambank Restoration

Team Members

Team MembersRebecca Podariu

Abigail Jacqmein

Chandler Harm

Ryker Van Brocklin

Faculty Supervisor

Aaron Mittelstet

Project Description

Development in the Cripple Creek Watershed has led to an increase in the amount of runoff in the area and the discharge of water through Cripple Creek, a tributary of Beal Slough. This has resulted in significant streambank erosion throughout the creek, especially in the portion managed by the Cripple Creek Homeowner’s Association. We have proposed a detention pond, widened stream channel, and a series of weirs to reduce the total volume and velocity of water in the stream.

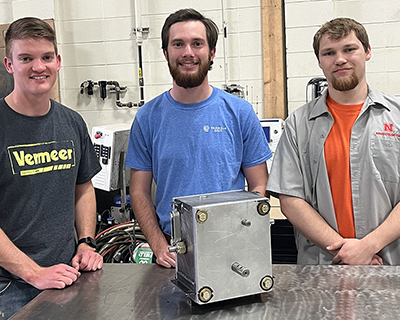

Quarter-Scale Tractor Transmission

Team Members

Team MembersSam Wilkins

Keaton Eichberger

Quentin Bock

Faculty Supervisors

Tami Brown-Brandl and Roger Hoy

Project Description

All of our team members are captains of the University of Nebraska-Lincoln Quarter-Scale Tractor Team. Each year, the Quarter-Scale team designs and builds a new tractor to take to a competition. We needed to design a new transmission for this year's tractor to implement four-wheel drive, a feature that has not been available on a UNL tractor in many years. Our transmission also needed to be compact and capable of transmitting over 500 foot-pounds of torque. Our final design meets all these goals and provides high and low gears in both forward and reverse.

Biological Systems Engineering

Mitigation of Contaminated Water at Grain Place Foods, Inc.

Team Members

Team MembersMalayna Wingert

Destiny Hrabik

Leah Boudreau

Ryan Winkel

Faculty Supervisors

Tami Brown-Brandl and Tom Franti

Project Description

Grain Place Foods, Inc., an organic farm north of Aurora, Nebraska, has been affected by pesticide contaminated runoff from a neighbor's non-organic farm. This has resulted in the loss of organic status for a section of their land, rendering it unusable for crop production. Grain Place Foods is seeking a sustainable solution. Our approach emphasizes the use of sustainable techniques that will guarantee the effectiveness of the solution while preserving the ecological balance of the farm. Our goal is to deliver a project that ensures the long-term sustainability of the farm, preserve its organic status, and have a positive impact on the environment. After conducting a survey assessment and evaluating the runoff volume from the neighboring farm, we designed an appropriately sized, dry-detention basin to slow down, clean, and divert contaminated runoff water. This basin will be lined with native prairie grass and is designed to have a sufficient detention time to render the water safe to re-enter the organic farmland, preventing future contamination and allowing the southeast corner of the farm to be reclaimed.

Design of University Small-Scale Dairy Processing Facility

Team Members

Team MembersPJ Hildebrand

Josh Arejola

Alicia Andersen

Faculty Supervisor

Tami Brown-Brandl

Project Description

Our group designed a milk processing plant to take raw milk from a small dairy – the newly proposed dairy on the University of Nebraska-Lincoln campus – and produce packaged milk that could be marketed and sold on campus and beyond. The small dairy production and processing operations are intended to be paired to enable small dairy producers across the state to mimic the processing operation and improve their profitability with a modular system design that meets their production volumes. Our tasks were to identify all relevant unit operations for the plant, conduct mass balance calculations to match production with output, determine utility needs for the plant by conducting heat transfer calculations, select appropriate equipment with prices, and summarize plant costs in a breakeven analysis with a Monte Carlo simulation.

Wireless Temperature Sensor to Monitor Adiabatic Heating in Foods

Team Members

Team MembersNathan Reineke

Isabella North

Maria Dominguez

Carter Hancock

Faculty Supervisor

David Jones

Project Description

Our team was tasked with designing a prototype wireless temperature sensor that can be used to monitor adiabatic heating of food and can withstand the pressure of High Pressure Pasteurization (HPP). Our project includes the making of a temperature sensor that can wirelessly log temperatures over a long period of time. This sensor is housed within a steel casing to allow it to withstand pressure up to 600 Megapascal Pressure Units (MPa).

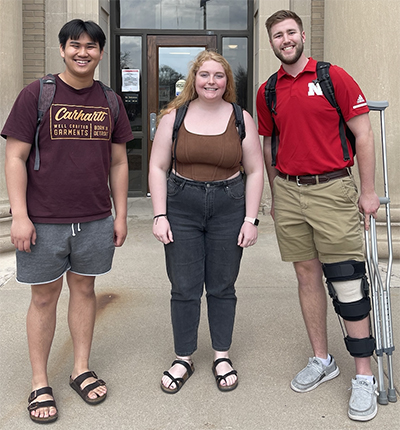

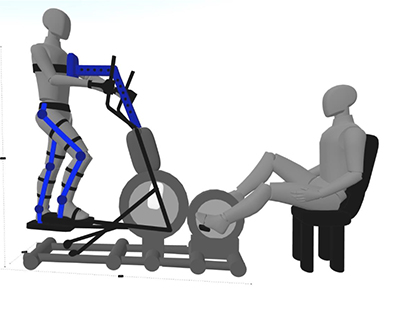

Assisted Elliptical for Patients with Impaired Motor Function

Team Members

Team MembersAdam Deutsch

Evan Marsh

Matthew Snyder

Junior Waka

Faculty Supervisor

Greg Bashford

Project Description

Doctors at the University of Nebraska Medical Center are seeking the design of an elliptical to be used in the rehabilitation of patients who have experienced a traumatic brain injury (TBI). Because some of these patients will have impaired motor function, doctors are hoping to “retrain” the patients’ brains with the assistance of a modified elliptical that will essentially help the patients "relearn" to use their legs to resume walking. Our design implements a trainer-assisted elliptical that also allows a person to guide the patient through the normal range of walking motion. The modified elliptical will have a center support the patient can strap themselves onto for support. Attached to the anterior side of the elliptical is a pedal system that is used to propel the elliptical – this can be done by a trainer if the patient needs assistance – and complete the full range of motion. Our team hopes to achieve the final goal of restoring motor function to TBI patients while also increasing flexibility in their hip joints and other lower-body joints.

Spidercam

Team Members

Team MembersTara Erker

Caitlyn Allen

Katelyn Kilpatrick

Patrick Wirball

Faculty Supervisor

Tami Brown-Brandl

Project Description

We worked on creating a scale model of the UNL Spidercam. This model is meant to help get kids interested in engineering and agriculture in a hands-on and interactive way. We designed multiple MATLAB codes to get images from the camera and determine the percentages of alive and dead plants in a given area and the density of plants in that area.

HOLEy cow! Duodenal Cannula

Team Members

Team MembersSophie Frappier

Emily Stratman

Uyen Nguyen

Faculty Supervisor

Greg Bashford

Project Description

A duodenal cannula is a T-shaped device that is surgically inserted into the first part (duodenum) of a calf’s small intestine immediately beyond the stomach to collect solid and liquid samples. This project was proposed because researchers are not easily able to collect both solid and liquid samples from a single duodenal cannula design. Our device combats these issues by having semicircular, flexible ends connected to stiffer, PVC plastic components. A washer on the outside of the device can be loosened to adjust to the size of a cow as it grows. Researchers collect samples from the duodenum by inserting a pipe (for liquid samples) or a bag (for solid samples) into the duodenal cannula. The researchers can then analyze the samples to assess ruminant nutrition in cows. This device will be implanted into a cow on East Campus to test its efficacy.

Improving Safety in the Surgical Field through Surgical Magnification

Team Members

Team MembersSarah Loftus

Kennedy Young

Aspen Schoenrock

Faculty Supervisor

Greg Bashford

Project Description

Our project aims to solve two important issues with surgeries: reducing fatigue and long-term injuries to surgical staff and improving the field of vision for the surgical team to both aid in the procedure and further reduce fatigue. Our team designed a harness-like device that will hold a camera to allow the surgeon to view the field through a monitor in order to reduce strain on the neck.

Cripple Creek Stream Restoration

Team Members

Team MembersJacob Stover

Joshua Ryder

Dayton Mays

Samuel Simpson

Faculty Supervisor

Greg Bashford

Project Description

With recent urbanization sweeping across much of the area surrounding Lincoln, our water resources systems can no longer handle the increased load of runoff water. Cripple Creek is one of those systems. Our team was tasked to analyze and design practices that will protect and sustain Cripple Creek through given storm events from erosion and dangerous flow conditions.

Design, Development, and Performance Evaluation of Canine Stifle Models

Team Members

Team MembersMarusha Ather

Lydia Saltz

Sarah Altman

Savannah Walvoord

Faculty Supervisors

Greg Bashford and Tami Brown-Brandl

Project Description

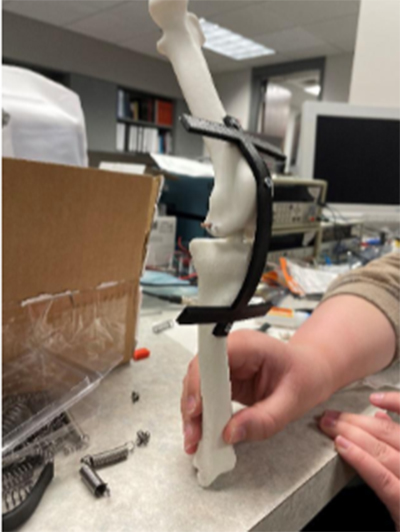

Cranial cruciate ligament (CCL) tears and medial patellar luxation (MPL) are two of the most common injuries in dogs. The cost of diagnosing these through imaging via MRI and CT scans is high. Veterinary students have been trained on cadaver legs to feel for the injuries by hand. However, cadaver legs are hard to source and don't last long. Our team has been tasked with designing a synthetic leg that mimics a healthy dog leg and a leg with CCL or MPL injuries. These models, created with 3D scanning and 3D printing technology, will aid in instructing veterinary students in the diagnosis of these ligament injuries.

Novel Fascia Closure Device

Team Members

Team MembersEvie Barnett

Terel Eisenbraun

Jevon Parrish

Brenna Wright

Faculty Supervisor

Greg Bashford

Project Description

Our device aims to gently re-align the fascia following abdominal surgery to prevent the splitting or busting open of the surgically sutured wound. This abdominal dehiscence can increase the risk of infection, evisceration and hernia formation. The fascia is a layer of connective tissue that surrounds the muscles within the abdomen and must be cut through to reach the organs of the abdominal cavity during surgery. Following surgery, the fascia often retracts more than other tissue layers such as the skin, making the closure of the fascia more difficult and more susceptible to tearing. The goal of our device is to ensure the fascia remains under constant tension to prevent retraction and gradually pull the fascia edges inward. Our device is intended to be used over one week to bring the fascia edges within four centimeters of one another. Following the removal of the device(s), the surgeon can successfully suture the fascia edges together. This, in turn, decreases the likelihood that dehiscence occurs as less tension will be placed on the final sutures holding the two edges of the fascia together. Multiple devices can be used at one time to span the length of the incision and help distribute the force required to bring the fascia edges together.

Chemical & Biomolecular Engineering

Greener Production of HDPE from CO2

Team Members

Kimberly Vander Woude

Andrew Meuret

Tommy Le

Faculty Supervisor

Yasar Demirel

Project Description

Polyethylene is the largest synthetic commodity polymer because it is widely used throughout the world due to its versatile physical and chemical properties. Global demand for high-density polyethylene (HDPE) is projected to reach 78 million tons by 2028. Currently, HDPE production uses non-renewable ethylene as a feedstock, which is obtained from an energy intensive and environmentally unfriendly petrochemical process called steam cracking. This project aims to produce greener HDPE as a sustainable alternative to traditional methods by using renewable energy and green ethylene. This innovative design will capture CO2, which would normally be emitted to the atmosphere, from a biorefinery and use it along with renewable, onshore wind energy to produce greener HDPE.

Kimberly Vander Woude

Andrew Meuret

Tommy Le

Faculty Supervisor

Yasar Demirel

Project Description

Polyethylene is the largest synthetic commodity polymer because it is widely used throughout the world due to its versatile physical and chemical properties. Global demand for high-density polyethylene (HDPE) is projected to reach 78 million tons by 2028. Currently, HDPE production uses non-renewable ethylene as a feedstock, which is obtained from an energy intensive and environmentally unfriendly petrochemical process called steam cracking. This project aims to produce greener HDPE as a sustainable alternative to traditional methods by using renewable energy and green ethylene. This innovative design will capture CO2, which would normally be emitted to the atmosphere, from a biorefinery and use it along with renewable, onshore wind energy to produce greener HDPE.

Using Greener Alternatives in the Production of Polyurethane Foam

Team Members

Aidan Larsen

Nate Wagner

Jorge Duenas Oliver

Faculty Supervisor

Yasar Demirel

Project Description

Polyurethane foam is a flexible polymer material generally used in furniture, bedding and insulation. In the process to produce polyurethane, there are multiple reaction steps to produce precursor materials. These steps each require toxic materials and produce high levels of waste and pollution. As the need for polyurethane grows as industrial capacity increases in developing parts of the world, a desire for a sustainable green production also increases. This design utilizes biomass as the starting material and applies novel methods to produce intermediate species to provide a greener solution for polyurethane production. While eliminating unwanted biproducts and limiting the use of toxic reactants, this design will produce approximately 9.6 million kilograms per year. The aim of this process is to decrease the environmental impact of polyurethane production while participating in a circular green economy.

Aidan Larsen

Nate Wagner

Jorge Duenas Oliver

Faculty Supervisor

Yasar Demirel

Project Description

Polyurethane foam is a flexible polymer material generally used in furniture, bedding and insulation. In the process to produce polyurethane, there are multiple reaction steps to produce precursor materials. These steps each require toxic materials and produce high levels of waste and pollution. As the need for polyurethane grows as industrial capacity increases in developing parts of the world, a desire for a sustainable green production also increases. This design utilizes biomass as the starting material and applies novel methods to produce intermediate species to provide a greener solution for polyurethane production. While eliminating unwanted biproducts and limiting the use of toxic reactants, this design will produce approximately 9.6 million kilograms per year. The aim of this process is to decrease the environmental impact of polyurethane production while participating in a circular green economy.

A Greener and Safer Production of Ammonium Nitrate, the Popular Nebraska Fertilizer

Team Members

Team MembersMakenna Smith

Payton Eyler

Jackson Stalnaker

Yaneth Montenegro

Faculty Supervisor

Yasar Demirel

Project Description

Ammonium nitrate is an odorless, white-to-gray compound that is used in fertilizers, military explosives, and some antibiotics. The majority of fertilizers include ammonium nitrate in the mix because nitrogen is abundant in both major parts of the compound (NH4NO3) – a mixture of ammonia and nitric acid. Both chemicals include nitrogen, which is one of the most important minerals needed for plant growth. Ammonium nitrate is very reactive and needs to have additives included to prevent misuse of the product. Since ammonium nitrate is very explosive other nitrogenous fertilizers have been tested. However, every other tested fertilizer did not perform as well. The fertilizer was either too low in nitrogen concentration or too volatile and would not absorb into the soil well. Ammonium nitrate is made in a process that utilizes an exothermic neutralization reaction between ammonia and nitric acid. As selling points, the design will make in-house ammonia to reduce carbon emissions, and 68% nitric acid will be purchased. The design will also be using renewable energy sources to reduce carbon emissions.

Green Production of Sodium Chlorate Using Renewable Energy & Safer Additives

Team Members

Dorian Bobbett

Laurel Hilger

Ashley Kasun

Elizabeth Garces

Faculty Supervisor

Yasar Demirel

Project Description

Sodium chlorate (NaClO3) is a necessary chemical for a wide variety of processes, including bleaching, cosmetics, paper production, and more. Current production of NaClO3 uses additives, such as sodium dichromate and hydrochloric acid, which are known to be hazardous to human health and the environment. The production of the chlorate electrolyte is also highly corrosive, leading to a costly and frequent need for maintenance on the electrolysis unit. An alternative additive, sodium permanganate, has been identified to shift toward greener and more renewable production to reduce the negative impacts currently associated with NaClO3 production practices. Our new process is capable of producing 80,000 metric tons of NaClO3 per year while minimizing operating costs, utilizing exclusively green energy, and increasing the overall safety of the process for employees, the environment, and the public at large.

Dorian Bobbett

Laurel Hilger

Ashley Kasun

Elizabeth Garces

Faculty Supervisor

Yasar Demirel

Project Description

Sodium chlorate (NaClO3) is a necessary chemical for a wide variety of processes, including bleaching, cosmetics, paper production, and more. Current production of NaClO3 uses additives, such as sodium dichromate and hydrochloric acid, which are known to be hazardous to human health and the environment. The production of the chlorate electrolyte is also highly corrosive, leading to a costly and frequent need for maintenance on the electrolysis unit. An alternative additive, sodium permanganate, has been identified to shift toward greener and more renewable production to reduce the negative impacts currently associated with NaClO3 production practices. Our new process is capable of producing 80,000 metric tons of NaClO3 per year while minimizing operating costs, utilizing exclusively green energy, and increasing the overall safety of the process for employees, the environment, and the public at large.

Sustainable Production of Ethanolamines From Air, Water, and Ethanol

Team Members

Team MembersAndrea Goertzen

Casey Nolte

Caydon McCracken

Jackson Young

Faculty Supervisor

Yasar Demirel

Project Description

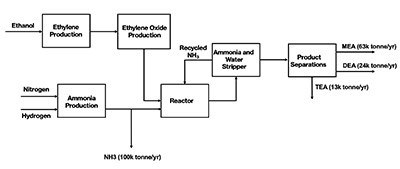

Ethanolamines are compounds widely used in cleaning agents, cosmetics, pharmaceuticals, etc. The primary feedstocks are ammonia and ethylene oxide, whose traditional manufacturing processes have typical carbon intensities of 1.5 tons and 1.9 tons, respectively, of carbon dioxide per ton product. This project seeks to reduce the carbon emissions of the process by using entirely renewable feedstocks of air, water and bioethanol, and renewable energy, the carbon intensity can be reduced significantly. This project also seeks to determine what economic landscape is viable to produce 100,000 metric tons per year of renewable ethanolamines.

Banana Peels as a Renewable Feedstock in Biorefineries to produce Citric Acid and Ethanol

Team Members

Team MembersArmon Watson

Anthony Alfieri

Josh Bauman

Maryam Al Jabri

Faculty Supervisor

Yasar Demirel

Project Description

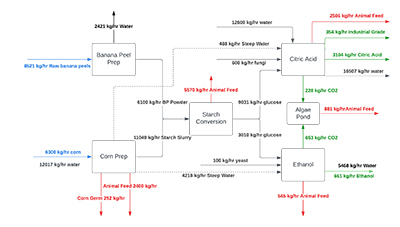

The purpose of this project is to produce 20,000 metric tons of anhydrous citric acid and 1.4 million gallons of 99 percent fuel grade bioethanol from banana peels and corn using the fungus Aspegillus niger, and the yeast Saccharomyces cerevisiae. The new addition to this plant reduces the waste of banana peels that usually end up in the landfill by capturing sugar from them to be used in fermentation. This report also proposes a more sustainable process that reduces the emission of greenhouse gases through carbon sequestration using monoethanolamine to produce food-grade carbon dioxide. This is accomplished when a split stream of carbon dioxide is fed to an algae pond that will produce oxygen and contribute to animal feed product. This process uses green electricity such as hydroelectric and solar power.

Sustainable Production of Nylon-6 Precursor from Lignin

Team Members

Team MembersMark Nusterer

Aiden Girthoffer

Ashley Miller

Nick Shaw

Faculty Supervisor

Yasar Demirel

Project Description

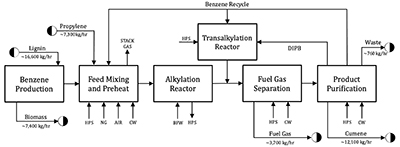

This project aims to address a problem in the production of cumene, a key commodity chemical used as a chemical intermediate for the production of phenol, acetone, nylon-6, and many other end products. Current cumene production processes rely on petrochemical feedstocks, which are unsustainable and environmentally damaging. The goal of this project is to design a green synthesis route for benzene, one of the required feedstocks for cumene, using readily available lignocellulosic biomass as a renewable carbon source. By utilizing waste products from multiple industries, such as paper and biorefineries, this sustainable production route seeks to produce 100,000 metric tons of cumene per year with a minimum purity of 98 wt% cumene. This alternative approach to the industry standard petrochemical precursors will lead to a more sustainable and environmentally friendly production of cumene across the industry.

The Green Production of Biodegradable Plastics from Waste CO2

Team Members

Isabelle Koehler

Justin Reed

Camron Watson

Stephen Yaghmour

Faculty Supervisor

Yasar Demirel

Project Description

Demand for biodegradable plastics is rapidly increasing due to the concern about landfill overflow, ecosystem pollution, and carbon emissions from conventional plastic creations. Polypropylene carbonate (PPC) is a biodegradable plastic that is traditionally produced from feedstocks that come from oil cracking, which produces numerous greenhouse gases and increases the threat of global warming. Green production methods struggle in being economically feasible but, with ongoing research and lowering of production and utility costs, the gap between economic feasibility and environmental sustainability is closing. PPC production involving green feedstocks and renewable energy sources will be important in lowering carbon emissions and encouraging increased use of biodegradable plastics that will not reside in landfills or ecosystems permanently. The goal of this project is to produce 20,000 metric tons of PPC per year by using only green feedstocks of primarily carbon dioxide and water. The required inputs for the production of PPC will be created mainly in-house, all starting with the two main feedstocks of carbon dioxide and water. Side products will also be produced in this process and will be sold to further increase economic feasibility. This project focuses on maximizing environmental sustainability, but another goal is to maximize profit where possible.

Isabelle Koehler

Justin Reed

Camron Watson

Stephen Yaghmour

Faculty Supervisor

Yasar Demirel

Project Description

Demand for biodegradable plastics is rapidly increasing due to the concern about landfill overflow, ecosystem pollution, and carbon emissions from conventional plastic creations. Polypropylene carbonate (PPC) is a biodegradable plastic that is traditionally produced from feedstocks that come from oil cracking, which produces numerous greenhouse gases and increases the threat of global warming. Green production methods struggle in being economically feasible but, with ongoing research and lowering of production and utility costs, the gap between economic feasibility and environmental sustainability is closing. PPC production involving green feedstocks and renewable energy sources will be important in lowering carbon emissions and encouraging increased use of biodegradable plastics that will not reside in landfills or ecosystems permanently. The goal of this project is to produce 20,000 metric tons of PPC per year by using only green feedstocks of primarily carbon dioxide and water. The required inputs for the production of PPC will be created mainly in-house, all starting with the two main feedstocks of carbon dioxide and water. Side products will also be produced in this process and will be sold to further increase economic feasibility. This project focuses on maximizing environmental sustainability, but another goal is to maximize profit where possible.

From Sugarcane to Paint: A More Environmentally Sustainable Production of the Whitest Pigment

Team Members

Joshua Wortman

Noah Berkenwald

Colling Hill

Carter Lund

Faculty Supervisor

Yasar Demirel

Project Description

Titanium dioxide is the whitest pigment known to mankind. A large impact of the existing refining process is the use of carbon-intensive materials such as petroleum coke. The carbon contained within petroleum coke is required to move the chemical reaction forward. Additionally, hazardous chlorine or sulfuric acid are used to create ionic salts in the traditional process. In our novel process, we seek to use alternative feed stocks to produce the whitest pigment. For the primary carbon source, we chose carbon monoxide derived from sugar cane bagasse, a waste material from the sugar cane industry. Additionally, instead of sourcing chlorine gas from manufacturers, who typically transport the gas via rail or pipeline, this manufacturing facility employs the use of desalination through electrolysis to produce chlorine gas.

Joshua Wortman

Noah Berkenwald

Colling Hill

Carter Lund

Faculty Supervisor

Yasar Demirel

Project Description

Titanium dioxide is the whitest pigment known to mankind. A large impact of the existing refining process is the use of carbon-intensive materials such as petroleum coke. The carbon contained within petroleum coke is required to move the chemical reaction forward. Additionally, hazardous chlorine or sulfuric acid are used to create ionic salts in the traditional process. In our novel process, we seek to use alternative feed stocks to produce the whitest pigment. For the primary carbon source, we chose carbon monoxide derived from sugar cane bagasse, a waste material from the sugar cane industry. Additionally, instead of sourcing chlorine gas from manufacturers, who typically transport the gas via rail or pipeline, this manufacturing facility employs the use of desalination through electrolysis to produce chlorine gas.

Green Production of Medical Grade Ethylene Oxide from Nebraska Bioethanol with CO2 Sequestration

Team Members

Team MembersStephen Rundgren

Rachel Gerdes

Cassie Perry

Faculty Supervisor

Yasar Demirel

Project Description

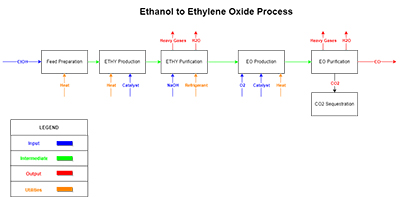

Ethylene oxide (EO) is a vital chemical used in the medical industry as a sterilization agent for medical devices and instruments. Approximately 50 percent of the world’s existing 20 billion medical devices require EO sterilization, and with an increased demand for medical procedures the industry is expected to grow by nearly 10 percent annually. Today, there is only one facility that provides this valuable resource to medical organizations in the United States. Our goal is to design a facility capable of producing 7.4 million pounds (or 3,700 tons) of 99.9 wt.% EO with reduced CO2 emissions. This project aims to demonstrate the process of converting bioethanol to the high-value-product EO and intense separation to achieve medical-grade purity. This also includes economic feasibility and sustainability analysis.

The Novel and Energy Efficient Production of Hydrogen and a Rubber Precursor

Team Members

Team MembersTim Williams

Elis Mangold

Dylan Hoppner

Carter Deming

Faculty Supervisor

Yasar Demirel

Project Description

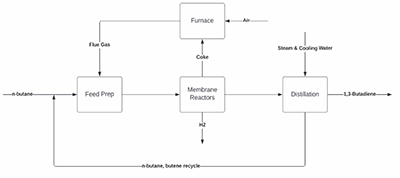

Butadiene is an organic compound produced from the dehydrogenation of butane and is an essential precursor in the production of synthetic rubber. Our group is seeking to improve the energy efficiency and profitability of its production by reducing the amount of energy necessary to achieve product conversion and through the creation of additional sources of revenue. This will be done using 405 kilotons of shale gas as the feedstock to produce 320 kilotons of butadiene and 20 kilotons of hydrogen per year. The initial feedstock will be sourced for $700 per ton. The products will be sold for $1,000 and $1,280 per ton respectively.

Electrical & Computer Engineering

Integrated Radiofrequency Indication System (IRIS)

Team Members

Chloe Ekborg

Crispin Corpuz

Dillon Falkinburg

Trevor Thomas

Faculty Supervisor

Herbert Detloff

Project Description

The team’s project was to create a persistent monitoring system for quantitatively analyzing structural attenuation characteristics across four discrete frequencies.

Chloe Ekborg

Crispin Corpuz

Dillon Falkinburg

Trevor Thomas

Faculty Supervisor

Herbert Detloff

Project Description

The team’s project was to create a persistent monitoring system for quantitatively analyzing structural attenuation characteristics across four discrete frequencies.

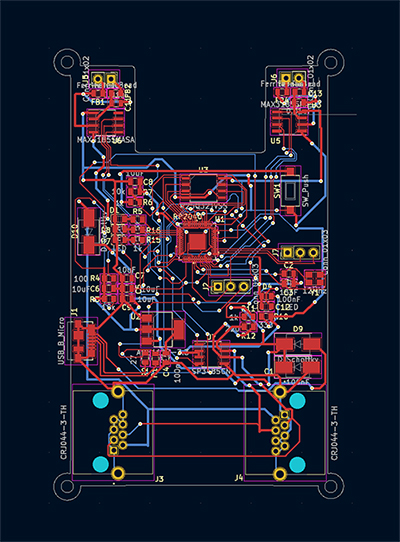

HANDY

Team Members

Team MembersAyden Uerling

Ryan Healey

Danny Schroeder

Maxx Seminario

Faculty Supervisor

Mark Bauer

Project Description

HANDY is a low-power, hand gesture-controlled human input device with Bluetooth connectivity. It provides an alternative to a traditional computer mouse and improves the accessibility and user experience for various applications. The device consists of a microprocessor with Bluetooth Low Energy capabilities along with a network of sensors mounted on custom printed circuit boards. HANDY is conveniently portable due to its internal rechargeable battery and compact design fastened to a glove that fits comfortably on the hand. HANDY bridges the gap between man and machine, paving the way to a more immersive future.

Wireless Competitive Buzzer System

Team Members

Team MembersHunter Poland

Paul Scalise

Ethan Warrick

Faculty Supervisor

Herbert Detloff

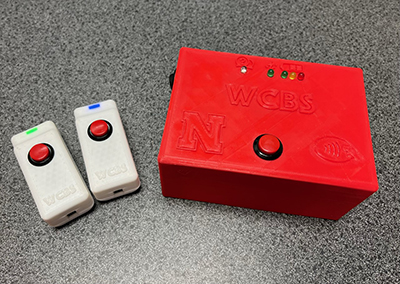

Project Description

The Wireless Competitive Buzzer System is an innovative solution for local school quiz bowl tournaments, designed to replace existing problematic wired buzzer systems. Our system uses up to eight wireless signaling devices (buzzers) connecting to a hub device using the Bluetooth Low Energy protocol. The hub device receives signals from each buzzer and determines which buzzer was pressed first and illuminates that buzzer. Additionally, a match scorekeeping webpage is provided by the hub via Wi-Fi. The team was responsible for all design, production and testing of this project’s hardware and software. The system was successfully completed according to the set parameters, fulfilling its required functionality. The project hasn’t been in a production environment and could likely be improved with feedback from that setting.

Time Correlated Single Photon Counter

Team Members

Team MembersLucas Miller

Josh Welling

Jon Boissy

Faculty Supervisor

Herbert Detloff

Project Description

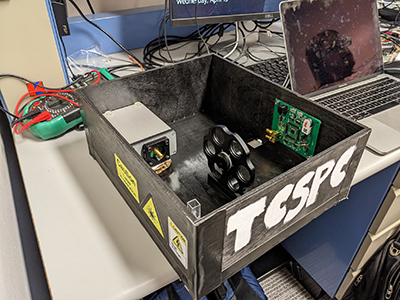

The purpose of this capstone project was to design and build timing circuitry to detect single photons. This project was designed in collaboration with the University of Nebraska Omaha physics department to measure fluorescent decay with sub-nanosecond precision. While our efforts to accurately detect single photons were not successful, the experimental enclosure was built, and the timing circuitry can accurately measure time delays between 14 nanoseconds and 500 milliseconds with roughly 100-picosecond precision. The detection circuitry has been redesigned to accept external signals such that our project is now a general-purpose high-precision timing circuit. To fulfill its original purpose, future work on this project should focus on photon detection before redesigning our timing circuitry.

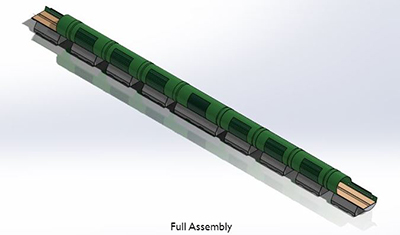

PEI Composite Curing Oven

Team Members

Team MembersJacob Craven

Dylan Lowery

Andre Tharp

Tyler Wolf

Faculty Supervisor

Mark Bauer

Project Description

The goal of this project is to create a curing oven for Pacific Engineering Inc. (PEI), located in Lincoln, Nebraska. PEI is a research and development company that specializes in the use of composite materials. They maintain equipment and capabilities to perform a variety of composite fabrication processes, including filament winding, resin infusion, hand lay-up, and compression molding. However, future projects require processing filament-wound cylinders exceeding 40 feet in total length. Currently, PEI uses an approximately 2,500 cubic-foot oven to process materials with a maximum length of 24 feet. In order to process parts exceeding 40 feet, an oven extension is needed and must be created. The oven must be able to control ramp rates, maintain accurate temperature control, and provide even heat distribution and airflow. The structure for the oven has already been constructed, so our main task was to create our own temperature-measuring devices by designing a board based on the Raspberry Pi RP2040 microcontroller. These boards will send information back to the main hub, which in this case is a Raspberry Pi 3B model. Along with these boards, we will create a GUI using a 7-inch touchscreen that can be interacted with by the user to input data. Additionally, we will install a heating element and a fan that can be controlled via the Raspberry Pi 3.

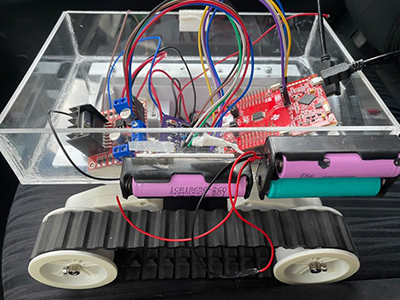

ROOMBA

Team Members

Team MembersNhu Le

Libo Dou

Cooper Schmer

John Buessing

Faculty Supervisor

Mark Bauer

Project Description

A Roomba is a cleaning robot that travels around a room and vacuums the floor. The machine has been a well-consumed product and has been on the market since it was invented. However, there are still constraints in the machine, including environment navigation. Some Roombas wander around directionless and have limits in their ability to see their surrounding environment, unable to neither detect obstacles nor estimate the size of the surrounding environment. This complication can initiate physical interaction between the robot and other objects or possibly cause the robot to be stuck in unwanted places. This project aims to create a device with three-dimensional vision and environment mapping for possible innovation of the Roombas visualization development. This robot will travel around a room and display images from various locations. The device will be able to navigate and map out its environment as well as avoid obstacles. Many electronic components, such as a camera, driving motor and microprocessors will be combined to successfully maximize the performance of the product. The goal of this project is to map out a room using 3D vision and be able to navigate the room using the created map.

Mechanical & Materials Engineering

B-36 Bomb Bay Tunnel Exhibit

Team Members

Team MembersDan Schnoor

Summer McGrew

Evan Harner

Alex Kolke

Faculty Supervisor

Kurt Palik

Project Description

The B-36 aircraft was equipped with a pressurized tunnel from the front to the back to allow the crew to pass through the unpressurized bomb bay. Our project is to create a scaled, hands-on exhibit of the pressurized tunnel and trolley system that crew would use to pass over the bomb bay in a B-36 bomber at the Strategic Air Command & Aerospace Museum in Ashland, Nebraska. The tunnel needs to accommodate adults and children, separate into sections for easy transport, and close off completely if needed.

Automated, Mobile, and Real-Time Control Chart Capable Check-Weighing System for Statistical Process Control of Filter End Cap Fill-Weights

Team Members

Team MembersGrant Meyer

Caleb Osmond

Merjen Palvanova

Ryan Salisbury

Samuel Whitney

Faculty Supervisor

Kurt Palik

Project Description

The scope of this project is to prototype and test a device to accurately measure, record, and track trends in end-cap fill weight using SPC software without disrupting current line-flow for Parker Hannifin's manually operated filter manufacturing lines with intent to extend to others. The result is an automated system, loaded manually, that logs fill-weights and updates a control chart (I-Chart) in real-time. Using “Western Electronic“ SPC rules, operators are alerted by an LED tower and an alert on-screen when fill-weights deviate from specification.

The system consists of two linear actuators, an LED light tower, DPDT relays, a cart with adjustable height, chutes, an NPN NO capacitive proximity sensor, a laser cut acrylic electronic housing, a 0.01-gram accurate scale, a device server for control, and custom 3-D printed mounts/fixtures. Matlab is used for low level communication to both the scale and device server as well as for plotting fill-weights in real-time on a control chart. Entry and exit chutes are designed to guide the end cap through the process.

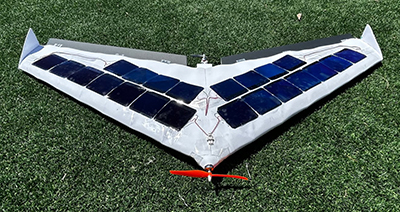

Solar Powered RC Airplane

Team Members

Team MembersHunter Bode

Markus Case

Kale Ensser

Jefferson Mai

Adolfo Diaz-Vargas

Faculty Supervisor

Kurt Palik

Project Description

Our team was tasked with designing a solar-powered RC aircraft with the deliverable of being able to maintain continuous, level flight on purely solar energy. Through brainstorming and research, our team decided on a flying-wing shaped aircraft incorporating a pusher-puller style motor system. The flying-wing design would allow for optimizing the number of solar panels that could be placed on our design while demonstrating the aerodynamic feasibility of this kind of airframe. Our prototype incorporates elevons/ailerons on each side as control surfaces to give our aircraft the ability to pitch and roll. The prototype is also capable of not only providing solar energy to the motors, but also to an internal battery.

Electronics within the body of the aircraft allow it to direct electrical power as needed between the panels, both motors, and battery. Through thorough testing, our prototype was refined to its final variation that proved its aerodynamic and solar-power functionality to meet the originally stated deliverables.